Active Pharmaceutical Ingredients (API) layering onto multi-particulate core materials has become an increasingly popular method of drug delivery in the pharmaceutical industry in recent years. The ability to control dosing, customize the dosing rate and reduce the risk of dose dumping along with the ability to create orally disintegrating tablets (ODT’s) with controlled release particles are all advantages to multi-particulate dosage forms. Freund-Vector’s Process Scientists and Grain Processing Corporation conducted a study that investigated whether a starch microsphere in the 50-80 micron range could be used as a core material to effectively layer a high payload of API onto while maintaining a finished particle size below 250 microns.

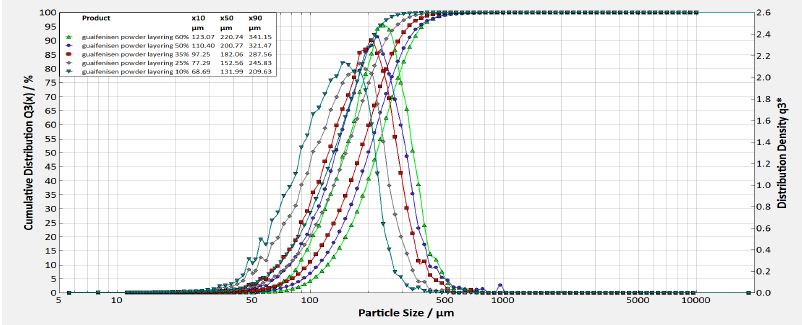

Particle size analysis (PSD) throughout the drug layering process revealed steady, uniform growth across the entire population throughout the entire process. The drug layering process was completed with Freund-Vector’s GRANUREX® GXR-35. Below is an illustrative chart that shows uniform particle growth across the distribution.

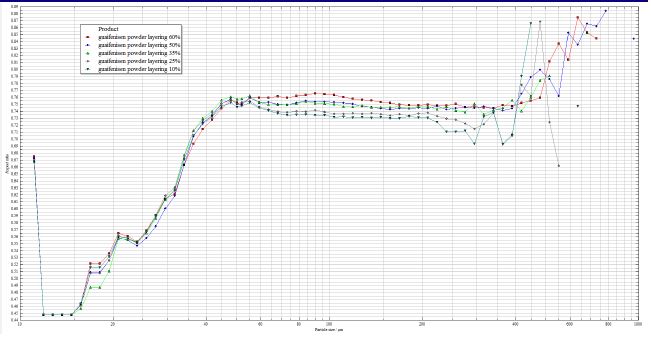

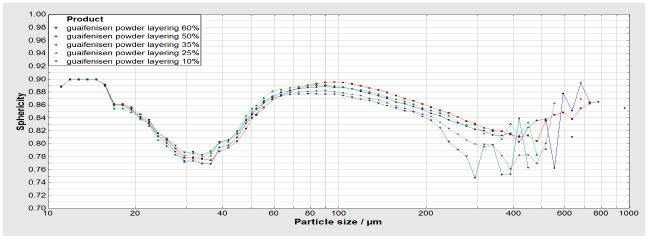

Shape analysis showed a steady increase in aspect ratio (roundness) and in sphericity (smoothness) throughout the process, with the highest value being present in the finished materials. Below are illustrative charts that show aspect ratio and sphericity.

The results of this study concluded that using starch microspheres as a core material for drug loading of API is a viable solution for obtaining high API payloads in a finished particle size below 250 microns. The high yields, excellent size and shape characteristics and excellent content uniformity results show advantages over other methods for obtaining high API loaded particles in that size range.

To read or download this poster, Please click here.