With any process, there are potential problems that need to be taken into consideration. In troubleshooting those problems, your first step should be to ensure that there are no equipment maintenance issues. Freund-Vector offers a Service Contract for routine equipment calibration and maintenance to assist with minimizing your equipment maintenance issues.

Once your equipment has been checked and your raw materials have been verified, then Freund-Vector recommends using a systematic approach to isolate and fix the processing problem. Freund-Vector offers structured seminars and on-site training programs to help establish those systematic troubleshooting techniques.

The objective of film coating processing is to spray a thin film, 20-100 µm, across the surface of the tablet to get even coverage. Too much air pressure will cause orange peel and poor coverage whereas not enough air will cause over wetting resulting in sticking and picking. The key to a successful film coating is consistency.

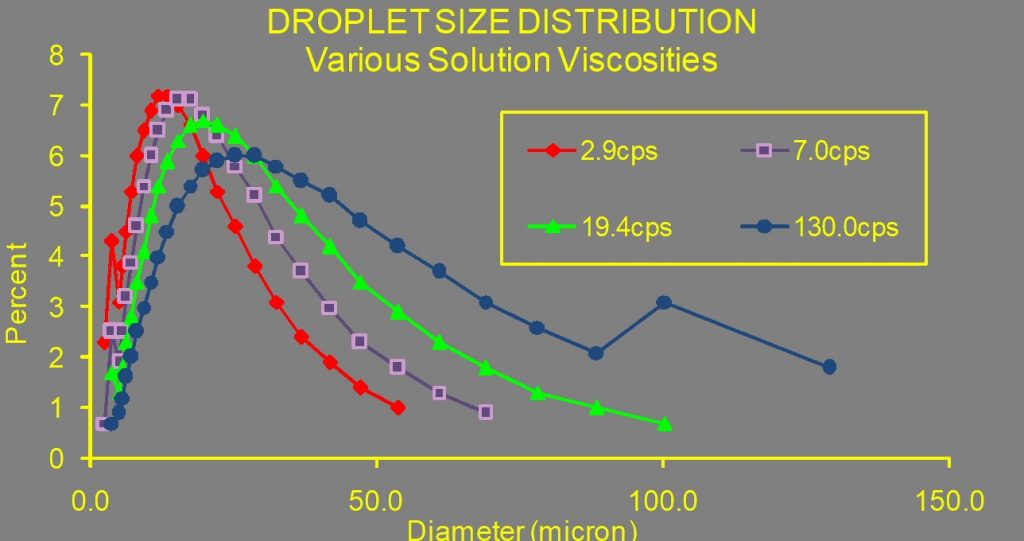

Below is an illustration that shows the relationship between solution viscosity and mean droplet diameter. As the solution becomes more viscous the droplet diameter will increase. An increase in the droplet size can lead to over wetting. Therefore, when using a solution of a higher viscosity it may necessary to increase the atomization air volume.

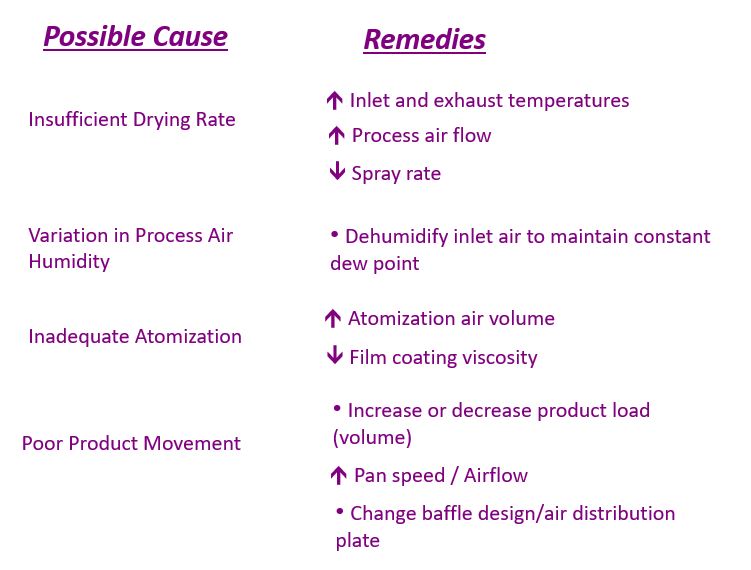

In the chart outlined below, Freund-Vector’s Process Scientists outline some common possible causes and remedies for over wetting.

Troubleshooting Film Coating Process Problems is part of the Freund-Vector Granulation and Coating Seminars held in Marion, Iowa and Villasanta (Milan Area). This three-day seminar integrates classroom lectures and hands-on laboratory sessions to provide a comprehensive learning experience. If interested in learning more about Freund-Vector’s seminars or on-site training programs, please send an email to sales@freund-vector.com.