Are you the one who is responsible for installation and startup at your organization? Are you being told that there cannot be any issues or delays? Wouldn’t it be nice to have some reassurances prior to your custom equipment being delivered? That’s what Factory Acceptance Tests (FAT) are for.

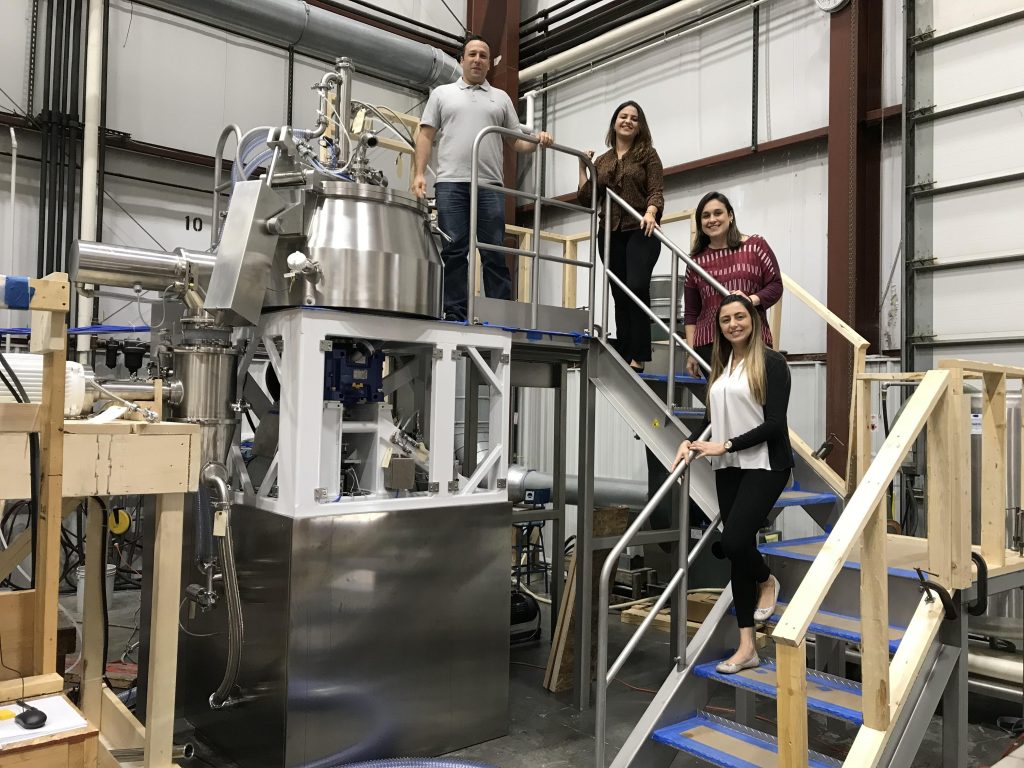

Freund-Vector’s Factory Acceptance Test (FAT) demonstrates the system design and manufacturing specifications set forth in the functional requirements document. A thorough mechanical, electrical and software test is performed on both the individual components and overall system. Customers get ‘hands on’ experience with the equipment and verify compliance with the purchase agreement prior to shipment.

Each Factory Acceptance Test (FAT) is unique because of the customer’s specific requirements so it is difficult to provide a FAT checklist. Instead, we can offer some general areas that are offered as part of Freund-Vector’s FAT:

- Documentation review

- Specification and detailed drawings

- Components functional tests

- System test

- Controls

- Validation

What are the benefits of participating in a Factory Acceptance Test (FAT)? Having the ability to see all the components of your system are functioning the way they should and within the range of operating specifications, provides reassurance that your installation and startup will not be delayed. Additionally, customers gain confidence as they interact with the equipment under the supervision of the Freund-Vector project team.

Upon completion of a Factory Acceptance Test (FAT), you can be confident in the equipment you are receiving and be ready to put it into production. We look forward to your next Factory Acceptance Test (FAT) with Freund-Vector.