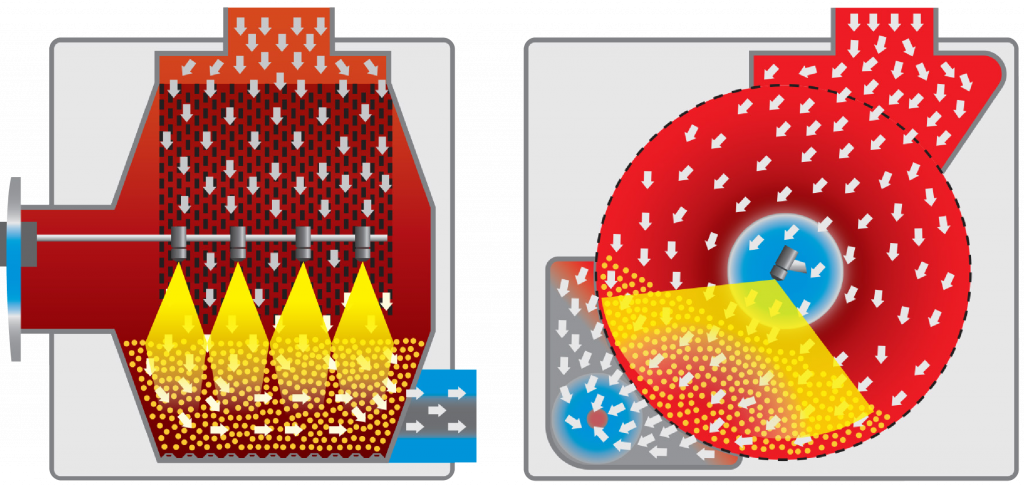

Fully Perforated HI-COATER® Systems

The HI-COATER® fully perforated tablet coating systems are used for the application of aqueous, solvent and sugar film coating for tablets and pellets. Pan volumes range from a 0.5L laboratory unit up to 1800L production units with batch sizes of 10% – 100% of the rated volume can be processed.

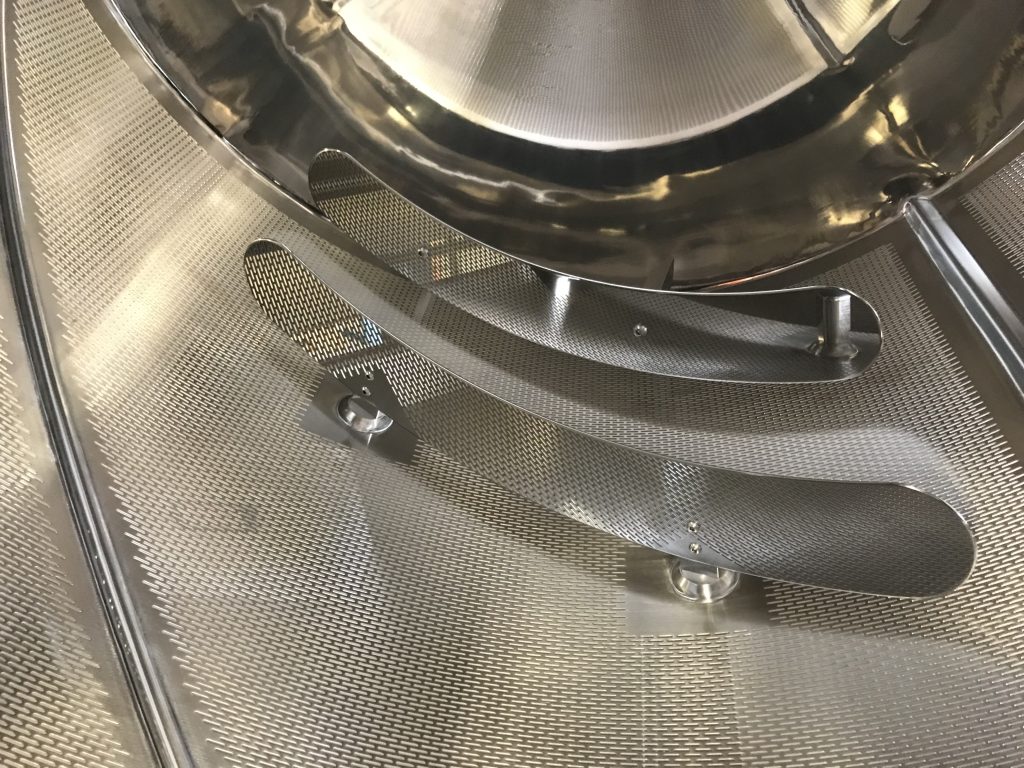

Anti-Marking Pans

FREUND’s coating pans are manufactured with a high-buff mirror polish, anti-slide baffles and slotted perforations which are proven to reduce tablet attrition when compared to round perforations.