GRANUMEIST® High Shear Granulation

The GRANUMEIST® High Shear Granulator/Mixer system is designed for efficient and homogeneous wet granulation of powders to form medium to high density granules with excellent flow and compression characteristics. The granulation process is very quick and is usually transferred into a FLO-COATER® fluid bed for drying. There are two styles of GRANUMEIST® granulators. Both styles produce equivalent granulation processes. There are non-processing advantages associated with both designs, which are discussed below.

Top Drive: GMX

The top drive GMX system has the mixer and chopper enter through the top lid. The bowl is lifted up to the blade for processing. Advantages include the ability for the bowl to be removed for cleaning inspection. Also, the seals for the mixer and chopper are removed from the processing area.

Bottom Drive: GMXB

The bottom drive GMXB system has the mixer blade enter the bottom of the process bowl. The chopper is mounted through the side. The bottom drive system is the more widely used type of high shear granulation system. It has an advantage in larger batch sizes (2000L versus 1200L max capacity for top drive systems) and can process up to 90% of the bowl rating (versus ~67% for top drive systems).

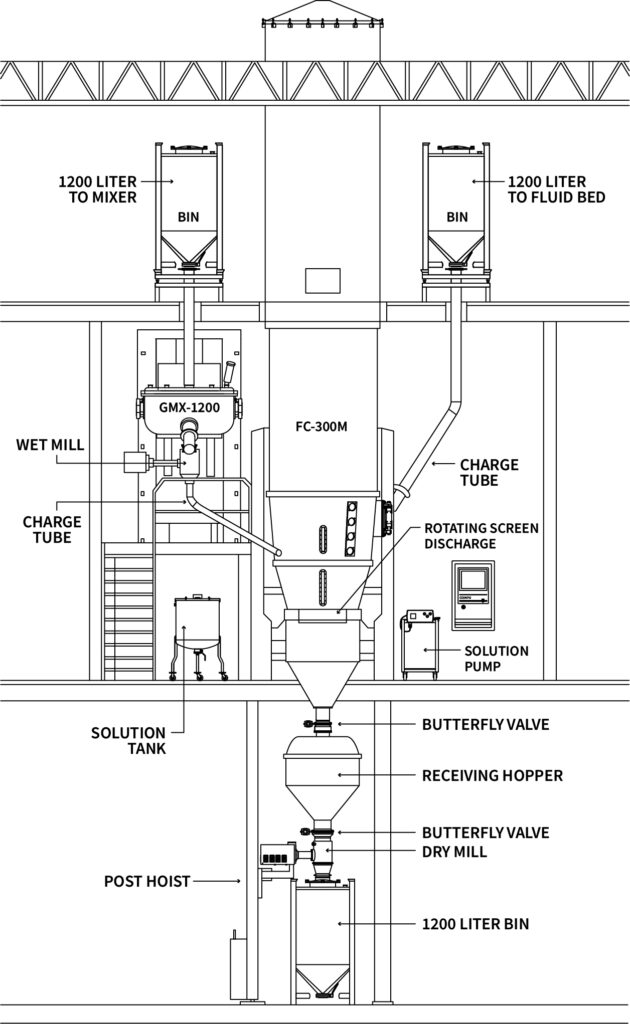

FREUND’s vertical granulation suites can be installed on several floors of a pharmaceutical facility. Gravity is utilized to provide a more efficient flow of product. The high shear mixer charges via vacuum or gravity. After the granulation process is complete, the mixer relies on gravity and a wet mill to control the product flow into the fluid bed dryer. Fluidization is maintained throughout the transfer process to assist product movement and to reduce clumping defects.

FREUND’s vertical granulation suites can be installed on several floors of a pharmaceutical facility. Gravity is utilized to provide a more efficient flow of product. The high shear mixer charges via vacuum or gravity. After the granulation process is complete, the mixer relies on gravity and a wet mill to control the product flow into the fluid bed dryer. Fluidization is maintained throughout the transfer process to assist product movement and to reduce clumping defects.