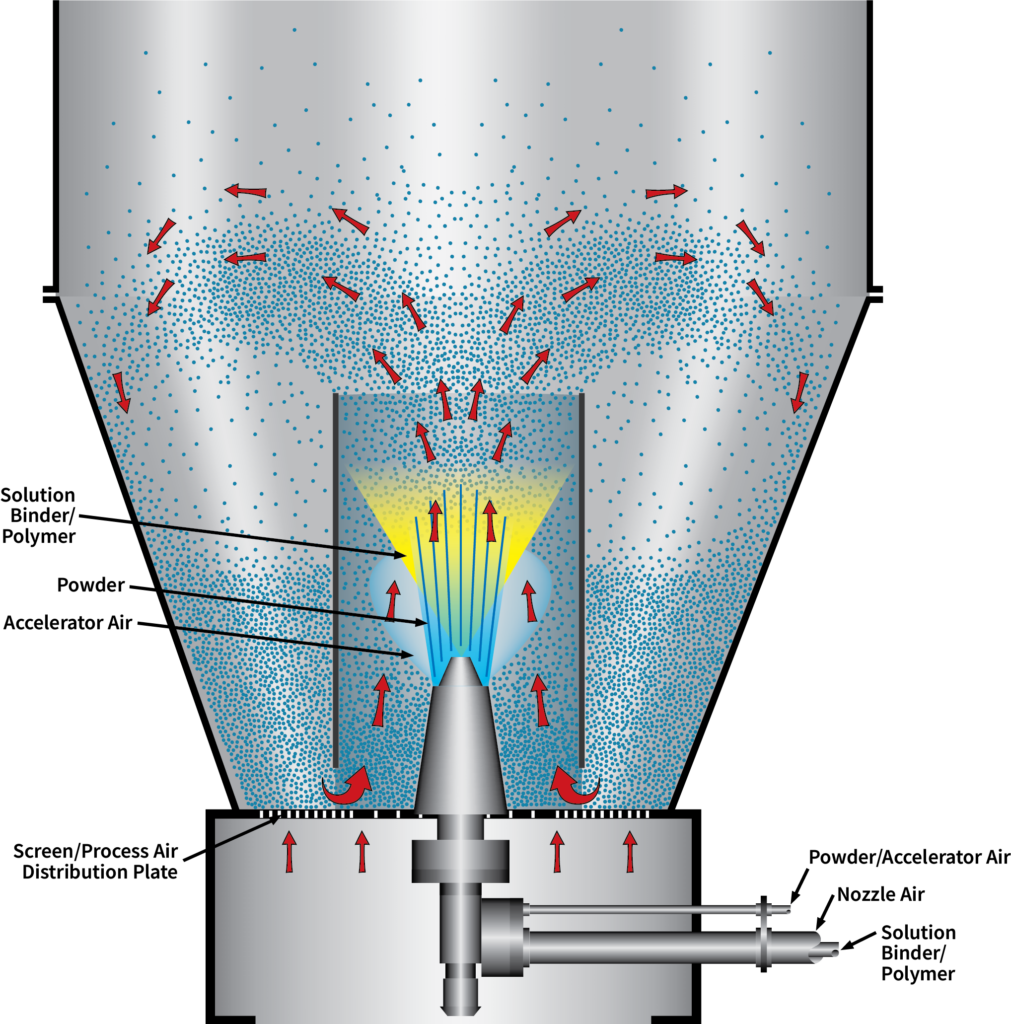

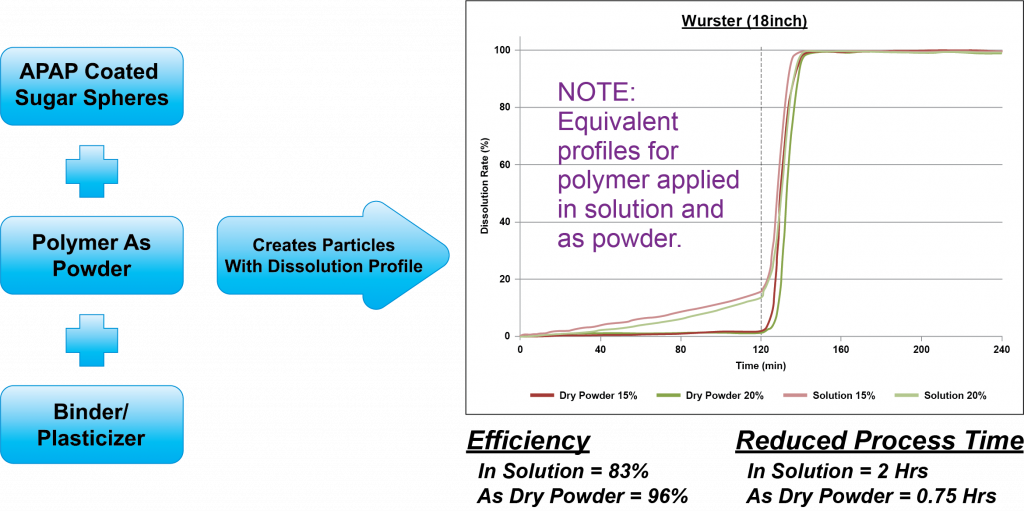

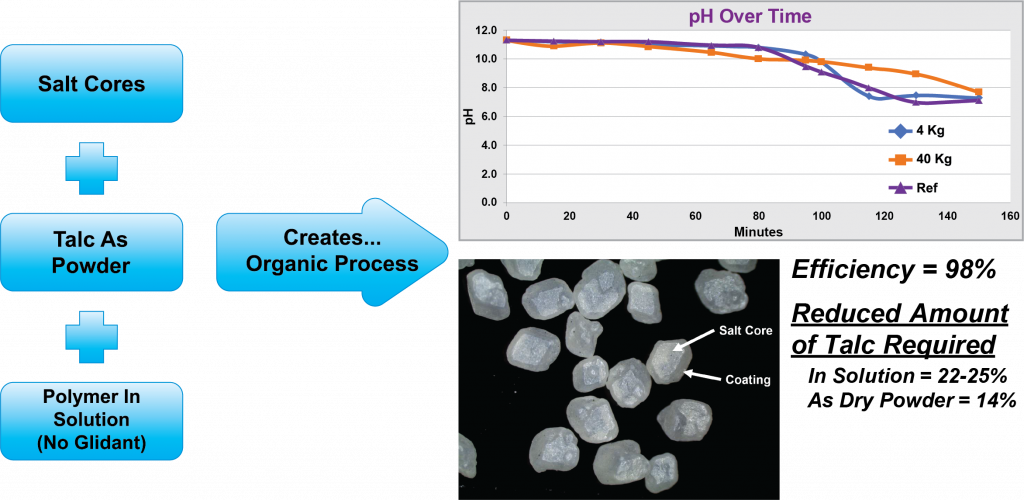

Freund’s patented Wurster Pro™ allows dry powder to be injected into the spray zone to enable coating multi-particulate cores with an enteric polymer. This method of dry powder layering decreases the application time needed for proper drug release or enteric protection.