What is GRANUREX®?

GRANUREX® is a processing insert that will fit within a FLO-COATER® fluid bed system.

What does GRANUREX® do?

By far, the GRANUREX® is the most powerful pellet/powder processor available in the market place. The applications are endless:

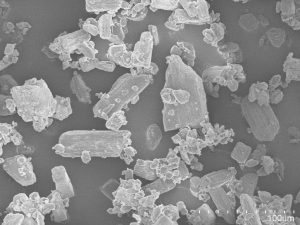

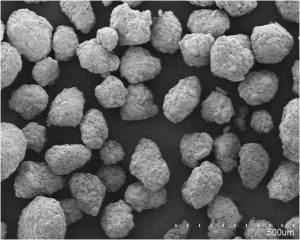

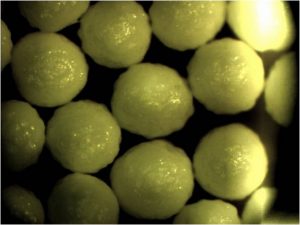

- Pellet Formation: Spherical granulation of powders into spherical granules/pellets (as low as 50 micron).

- Solution/Suspension Coating: Precisely applying a coating onto a core material

- Dry Powder Layering: Rapidly increasing size of pellet by directly applying a powder. The powder could be an API (Active Pharmaceutical Ingredient), a controlled release polymer, or an excipient.

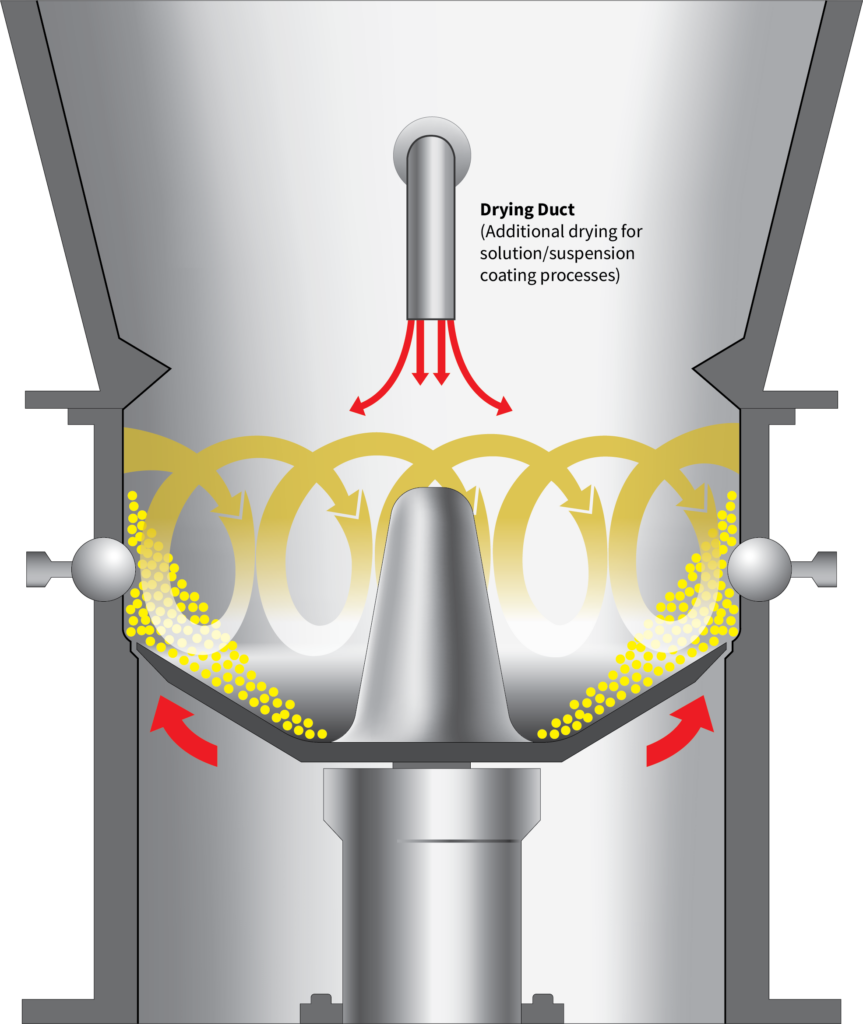

How does GRANUREX® work?

Finely divided/Micronized API and excipient is loaded on to a conical rotor. Air atomized binder liquid is applied to the powder. Rotor energy is used to densify and spheronize the powder resulting in uniform granules.

Applying solution or suspension based active or polymer via air atomizing spray gun. The process may include application of glidant or other excipient via the precision powder feeder to enhance the rate of spray and/or the amount of solids applied per unit time. Some actives and polymers are adhesive as they dry, applying glidant via the powder feeder can improve spray rates dramatically by mitigating this adhesive nature. In some cases this can allow solid content in solution/suspension to be doubled. Conventionally, glidant may be added to the suspension before spraying. By not adding it to the suspension, gun blockage is eliminated, suspension preparation is simple and the process is streamlined.

A powder feed system can be integrated into the GRANUREX® process, which greatly increases the rate of pellet formation. Finely divided/Micronized API and/or micronized polymer and/or micronized excipient is loaded in to a precision powder feeder. Core particles from 100 to 2000+ microns are loaded on to a conical rotor. A small amount of binder, plasticizer or liquid solvent is atomized and sprayed on to the core particles while the dry micronized powders are fed in to the cores via the precision powder feeder. Rotor energy and the precise balance of micronized powder and liquid addition results in very fast coatings of active, polymer or combinations that would take hours or days if applied conventionally from solution. Product movement on the rotor ensures very high uniformity.