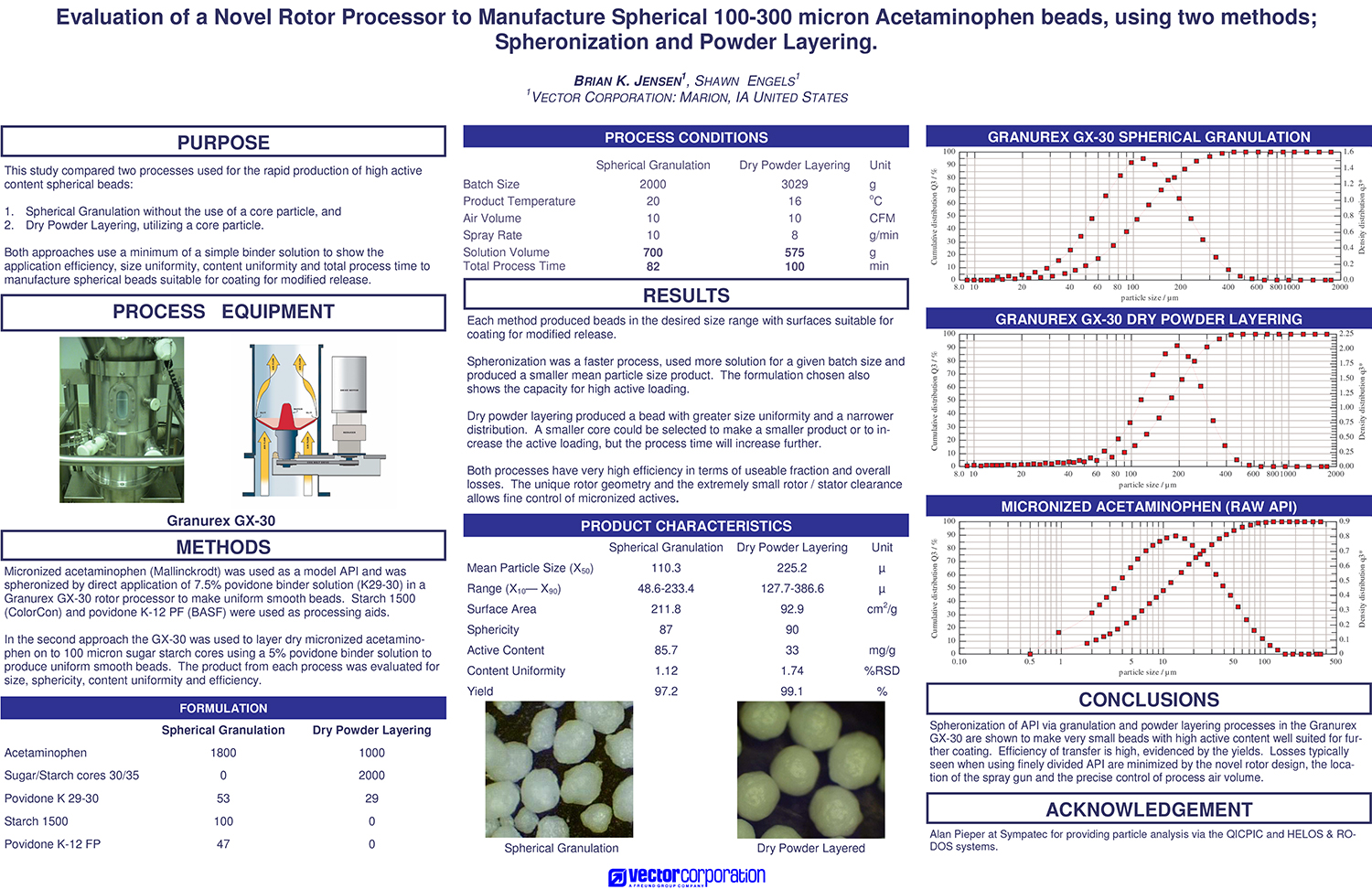

Novel Rotor GXR Process – 100-300 Micron APAP Beads via Spheronization-Powder Layering

This study compared two processes used for the rapid production of high active content spherical beads: 1. Spherical Granulation without the use of a core particle, and 2. Dry Powder Layering, utilizing a core particle. Both approaches use a minimum of a simple binder solution to show the application efficiency, size uniformity, content uniformity and total process time to manufacture spherical beads suitable for coating for modified release.