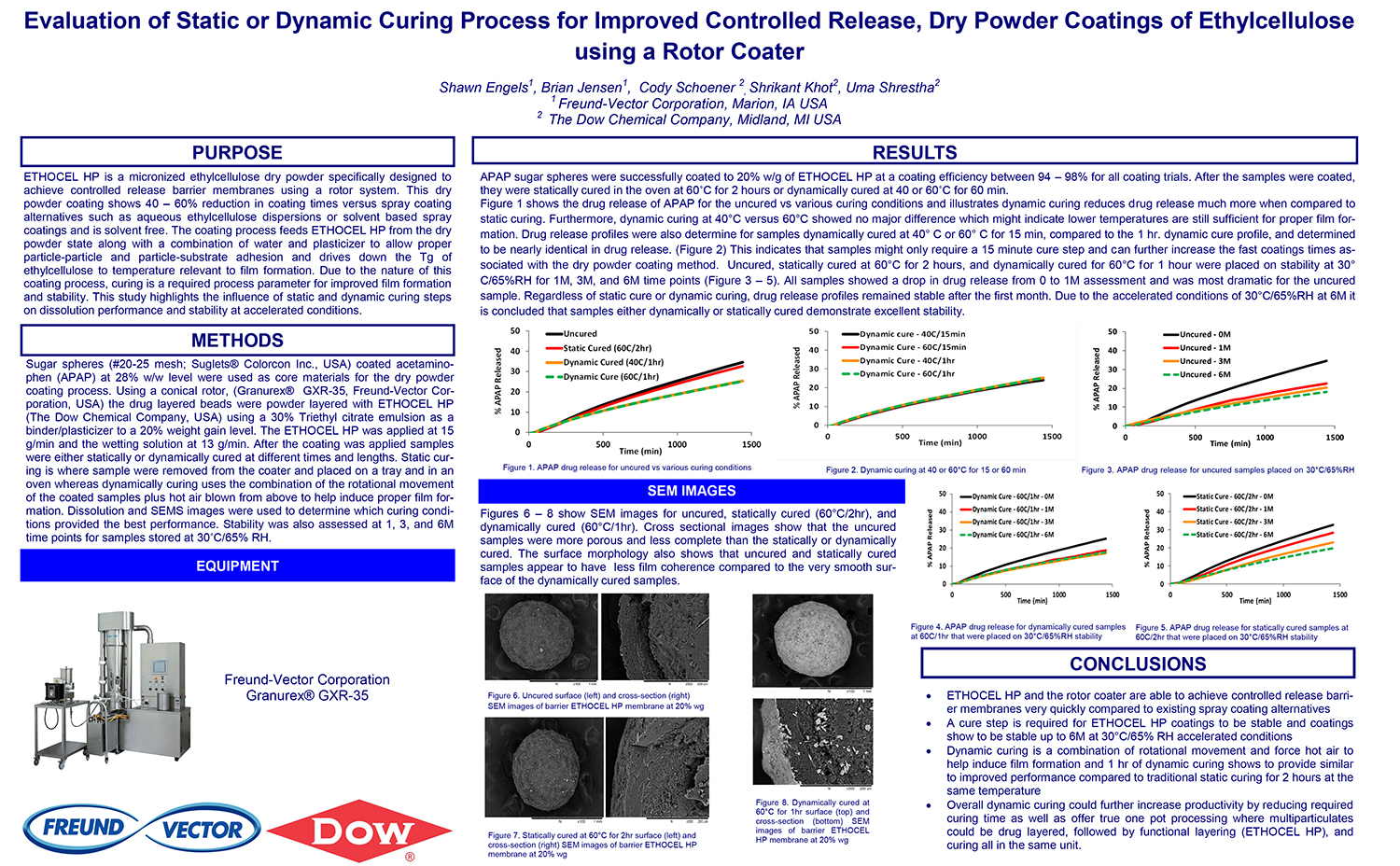

Evaluation of Static or Dynamic Curing Process for Improved Controlled Release, Dry powder coatings of Ethylcellulose using a Rotor Coater

ETHOCEL HP is a micronized ethylcellulose dry powder specifically designed to achieve controlled release barrier membranes using a rotor system. This dry powder coating shows 40 – 60% reduction in coating times versus spray coating alternatives such as aqueous ethylcellulose dispersions or solvent based spray coatings and is solvent free. The coating process feeds ETHOCEL HP from the dry powder state along with a combination of water and plasticizer to allow proper particle-particle and particle-substrate adhesion and drives down the Tg of ethylcellulose to temperature relevant to film formation. Due to the nature of this coating process, curing is a required process parameter for improved film formation and stability. This study highlights the influence of static and dynamic curing steps on dissolution performance and stability at accelerated conditions.