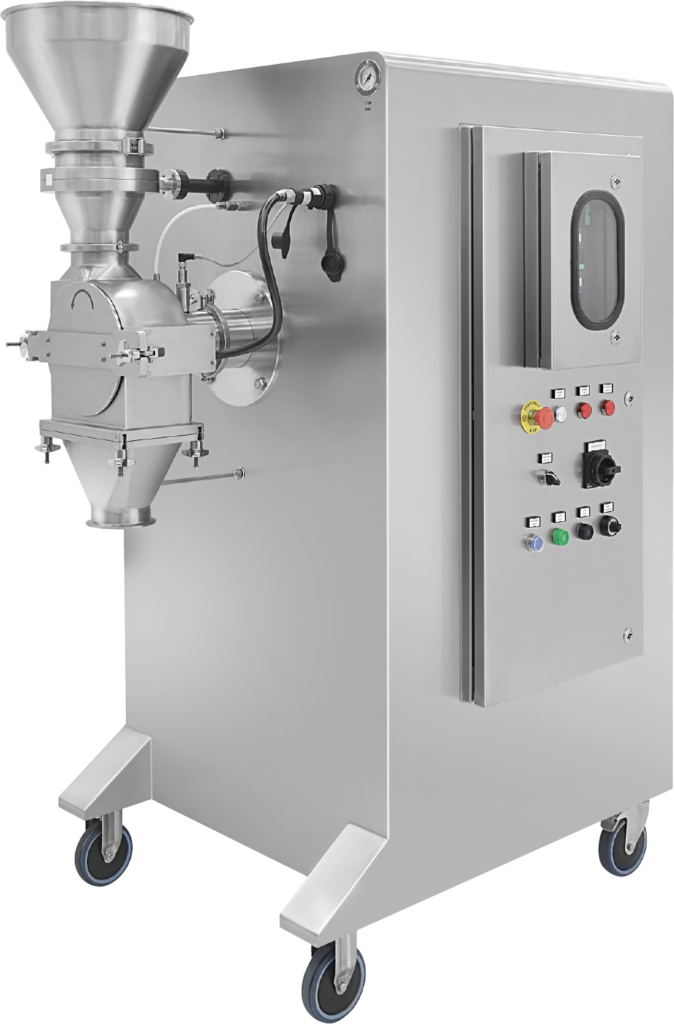

Hammer Mill

Equipment used to mill dry powder and granule clots or agglomerates. The flat or sharp blades (hammer and knives) alternately installed on the variable-speed rotor break up and reduce the size of the product clots during rotation. The product eventually reaches the desired size and passes through the screen holes.