The 9th International Granulation Workshop took place in Lausanne, Switzerland on June 26-28, 2019. The granulation conference is the place to showcase the latest in agglomeration, granulation and particle technology with attendance from a range of universities and industry worldwide.

The use of near infrared (NIR) reflectance has rapidly grown partly due to demands of process analytical applications within the pharmaceutical industry. The non-invasive and non-destructive nature of measurements makes NIR a powerful tool in analyzing pharmaceutical solids. NIR’s benefits include: increased process understanding, better process control and improved quality of drug products.

Freund-Vector’s Andrea Gelain, Process Development Scientist, presented a poster entitled, “PAT Monitoring of Coating Pan by NIR: PLS Method Calibration Approach”. The poster showed the coating pan monitoring process trend using NIR technology to determine the weight gain and coating thickness of the coated tablets in real time.

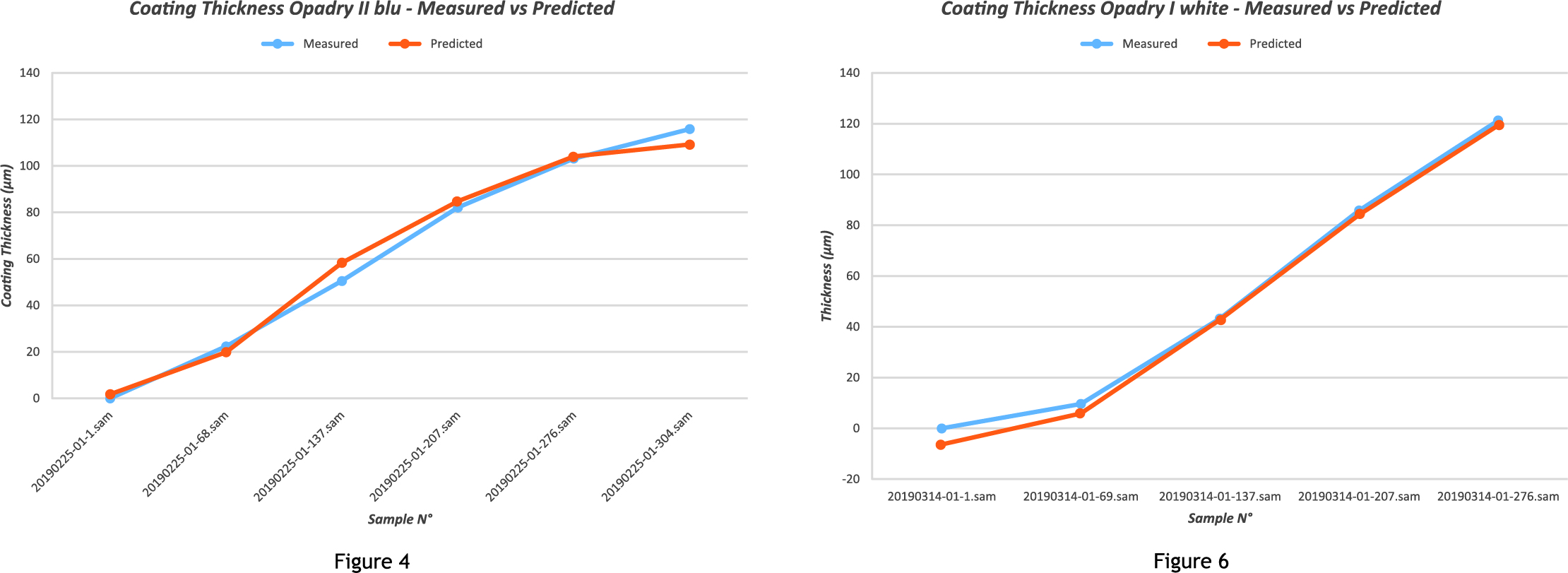

Fig. 4 and Fig 6 represent the comparison between the measured coating thickness.

The equipment used was a Freund-Vector LDCS Pilot HI-COATER® equipped with a Viavi MicroNIR PAT-U.

Andrea’s conclusion showed a very strong correlation between the absorbance read by the NIR instrument and the determined coating thickness and weight gain. The reproducibility of the precision of the PAT monitoring can allow process control without the need of constant sampling and at-line analysis.

To read or download this poster, Please click here.

If interested in learning more about Freund-Vector’s HI-COATER® technology, please visit freund-vector.com or send an email to sales@freund-vector.com.