Differences Between Top and Bottom Drive Processors

Freund-Vector’s GRANUMEIST® High Shear Granulation system is designed for efficient and homogeneous wet granulation of powders to form medium to high density granules with excellent flow and compression characteristics. There are two styles of GRANUMEIST® granulators, Top Drive (GMX) and Bottom Drive (GMXB). Both top-driven and bottom-driven granulators produce equivalent granulation processes.

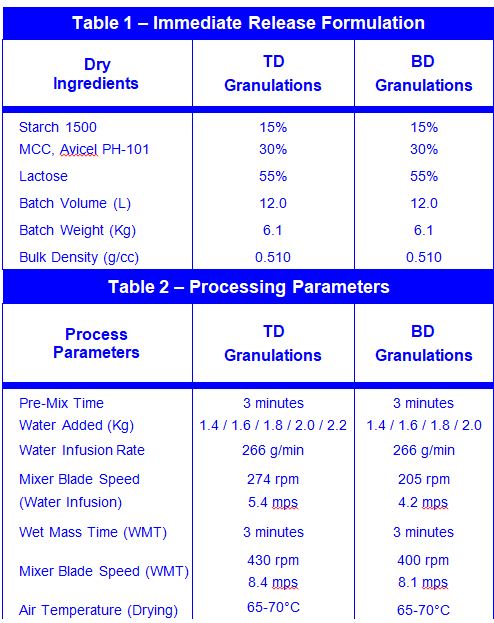

To prove this statement, Freund-Vector conducted a study comparing Wet-Granulation Processes Using Top-Drive and Bottom-Drive High-Shear Granulators. The results of the study showed there is no significant difference in product bulk density or rise in temperature.

So, if there are no processing differences between the two designs, what are the differences?

Top drive systems have the following non-processing advantages:

- The blade, chopper and bowl are easily separated for ease of cleaning.

- Requires less floor space.

- Removable mixing bowl allows for direct charge from the fluid bed.

- No need for lifts, platforms and inspection devices. Makes top drive systems less expensive.

Bottom drive systems have the following non-processing advantages:

- Offers the ability to utilize 12 bar construction instead of isolation valve on the transfer tube.

- Ability to go to 90% batch capacity vs 70% on top-drive.

- Provides a smaller gap between bottom of bowl and blade.

To learn more about Freund-Vector’s GRANUMEIST® High Shear Granulation Systems, please visit Freund-Vector’s YouTube Channel. To read and download the poster, please click here.