The purpose of this research was to compare two processes, an established Wurster coating process and a GRANUREX® process for producing 100-300 micron Omeprazole coated beads to determine if advantages were present in either approach. Efficiency, uniformity and total process time were the three key areas that this poster focused on.

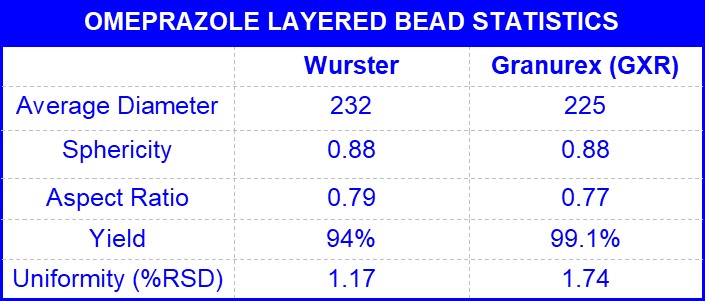

Below is a chart that outlines the results for particle size, sphericity, content uniformity and yield.

Our conclusion shows that an alternative processing method for the preparation of very small spherical active beads is shown. The sphericity and surface smoothness of the spheronized beads is ideal for modified release coating, and significant time savings can be achieved over traditional methods requiring the application of large volumes of active suspension.

To read or download this poster, Please click here.