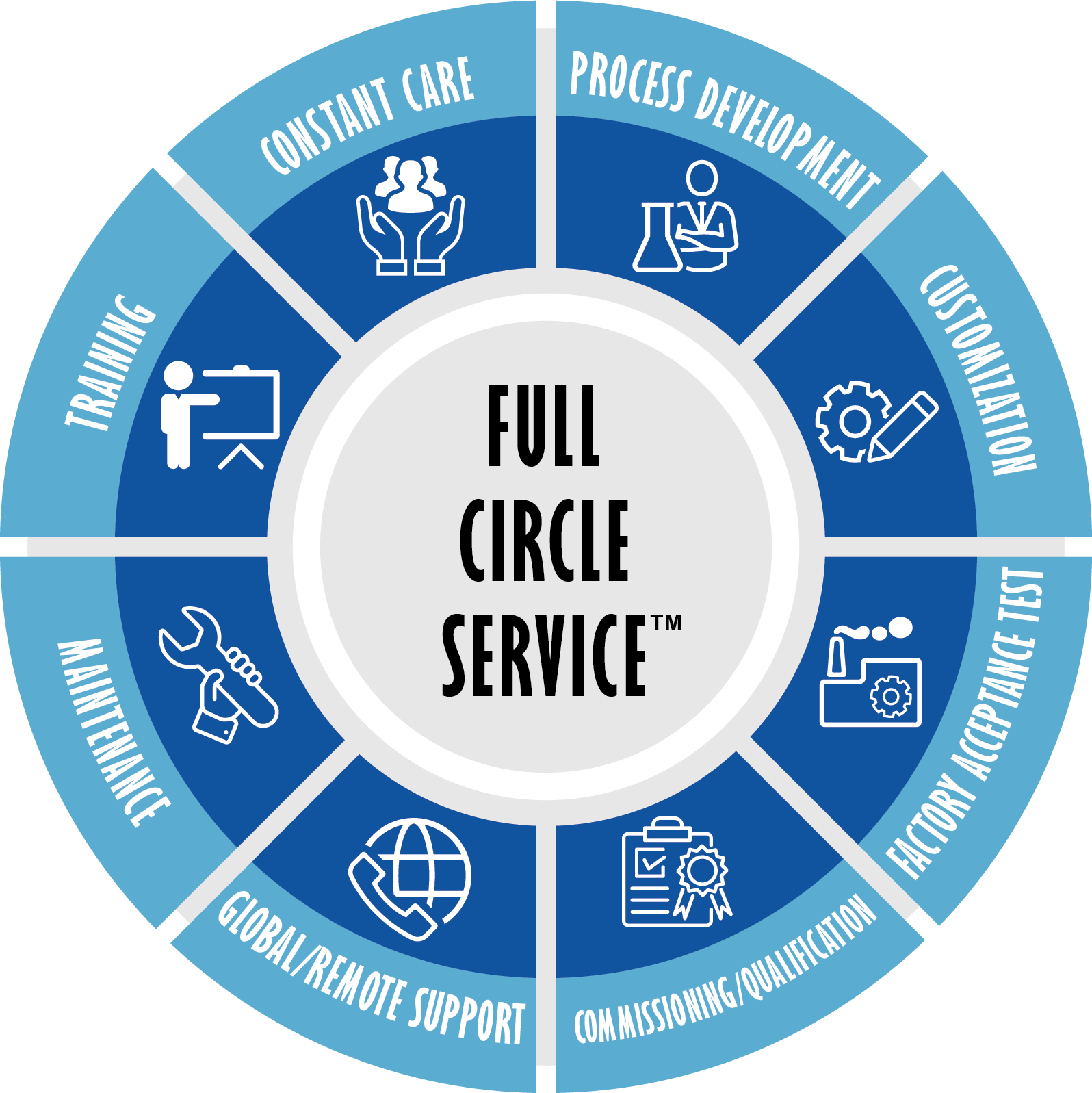

CONSTANT CARE:

Our mission is to become your most trusted and valuable supplier. We provide quality and effective services that consistently focuses on your individual needs, desires, and abilities. This can incorporate things like our global sales network, pre-sale consultation, facility layouts, and much more. When you buy from FREUND, you become part of our family with comprehensive lifetime support for everything we supply.

PROCESS DEVELOPMENT:

FREUND process development scientists are available to support our customers at all phases of the development process. Whether it is exploratory/conceptual studies or scaling up to full scale manufacturing – our process development scientists are fully trained and available to provide processing services. In addition, training and education is another key aspect of what our process scientists provide our customers. When a client purchases from FREUND, they have immediate access to our process development group at all stages of the equipment life cycle.

CUSTOMIZATION:

The pharmaceutical industry is a very diverse ecosystem. In order to meet the needs of the market, we provide our customers with specific solutions to make their unique manufacturing processes efficient and effective. We accomplish this by offering a wide range of standard and customized options for all of our equipment. FREUND is structured from top to bottom with customization in mind. Our Mechanical, Controls, Validation, Technical Publications, Project Management, Customer Service, Laboratory, Manufacturing, Assembly and Sales groups are all specifically structured to allow FREUND to engineer, manufacture, build, test and ship a high quality, custom solutions to our customer each and every time.

FACTORY ACCEPTANCE TEST:

No competitor goes to the extent of demonstrating their equipment during the Factor Acceptance Test better than FREUND. A thorough mechanical, electrical and software test is performed on both the individual components and overall system. A complete dry-run – including software, AHU hookups, and CIP demonstrations, are constantly demonstrated on the factor floor, PRIOR TO SHIPMENT! Customers get ‘hands on’ experience with the equipment as well as the ability to run placebo or actual product to verify compliance with the purchase agreement. Having the ability to see all the components of your system functioning the way they should and within the range of operating specifications, provides reassurance your installation and startup will not be delayed.

COMMISSIONING/QUALIFICATION:

FREUND tests the equipment and designs it manufactures to ensure compatibility and quality of the equipment to suit your final process needs.

After manufacture, the equipment undergoes a rigorous calibration and checkout at our factory using our Internal Equipment Acceptance Testing protocols that challenge the equipment throughout the operating range. Calibration and IQ/OQ (Installation and Operational Qualification) protocols are available for all FREUND product lines. These protocols have been used during the Internal Equipment Acceptance Process and undergo review and revision prior to final release.

These manufacturing and testing processes undergo continuing improvement via FREUND’s certified ISO-9001 guidelines and procedures.

Commissioning services are available to assist in final placement of the equipment on-site, verify the installation and utilities to the machine, Calibrate the instrumentation and equipment, perform organized and detailed checks of the equipment in a sequence that helps provide an optimal commissioning experience. This is especially helpful for more complex equipment that requires unique expertise to properly install and verify the installation.

The Commissioning and Qualification of the equipment is backed by FREUND’s team of Project Management, Manufacturing, Engineering and Process Scientists to make sure your new equipment is installed properly, functions correctly, and reliably operates for years to come.

GLOBAL SUPPORT:

Freund’s service and control engineers are available to answer customer questions. One of the best means we have to do that is through remote support. With current remote access technologies, we are able to connect to your control system and see first-hand what is happening in order to solve issues quickly and completely. Once issues have been resolved or steps needed for resolution have been determined, we work with you to determine if there are any validation impact to the system and work through those to get your equipment back to full operation as soon as possible.

MAINTENANCE:

FREUND has expert service technicians available, around the clock and around the globe, to make sure a breakdown doesn’t turn into a meltdown! No matter where you are, our trained technicians will get you up and running again quickly and safely to minimize down time and maximize productivity.

One Stop Shop for Spare Parts

FREUND equipment has been designed with the benefit of decades of experience to provide you with the highest performance and exceptional reliability. To ensure safe, reliable, and ideal operation of your equipment at all times, the use of original designed spare parts is necessary to the service life. The spare parts come to us first, we inspect them to make sure they were built according to the manufacturer, then off to your facility.

TRAINING:

We can train your staff on location or remotely to ensure your business benefits from maximum efficiency and minimum downtime; this will save you time and money and give your team the most productive and applicable learning experience possible.

Services Include:

• Operator Training

• Technical/Maintenance Training

• Machine Process Training

• Processing Seminars at FREUND Facility

• And More