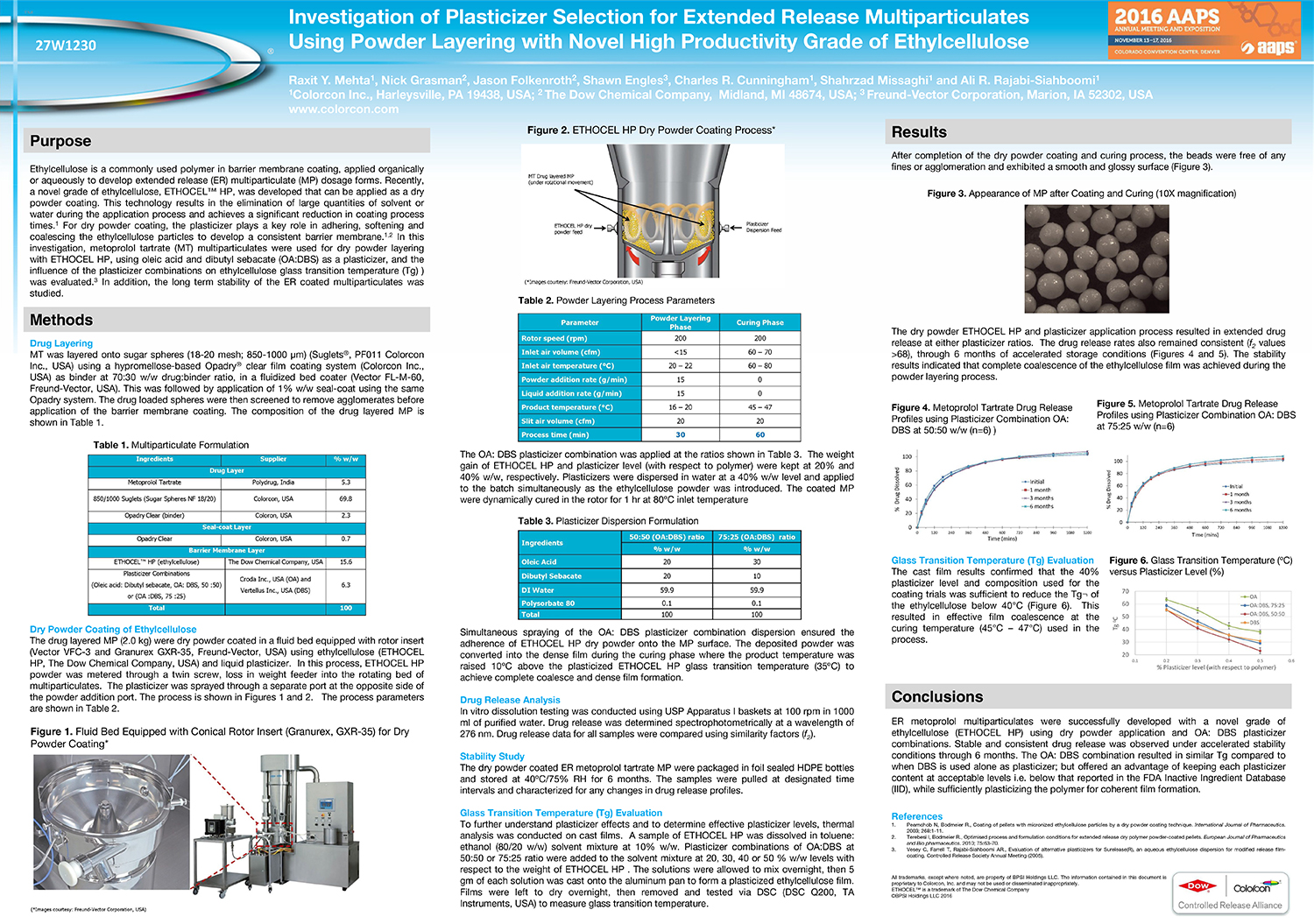

Investigation of Plasticizer Selection for Extended Release Multiparticulates Using Powder Layering with Novel High Productivity Grade of Ethylcellulose

Ethylcellulose is a commonly used polymer in barrier membrane coating, applied organically or aqueously to develop extended release (ER) multiparticulate (MP) dosage forms. Recently, a novel grade of ethylcellulose, ETHOCEL™HP, was developed that can be applied as a dry powder coating. This technology results in the elimination of large quantities of solvent or water during the application process and achieves a significant reduction in coating process times.1 For dry powder coating, the plasticizer plays a key role in adhering, softening and coalescing the ethylcellulose particles to develop a consistent barrier membrane.1,2 In this investigation, metoprolol tartrate (MT) multiparticulates were used for dry powder layering with ETHOCEL HP, using oleic acid and dibutyl sebacate (OA:DBS) as a plasticizer, and the influence of the plasticizer combinations on ethylcellulose glass transition temperature (Tg) ) was evaluated.3 In addition, the long term stability of the ER coated multiparticulates was studied.