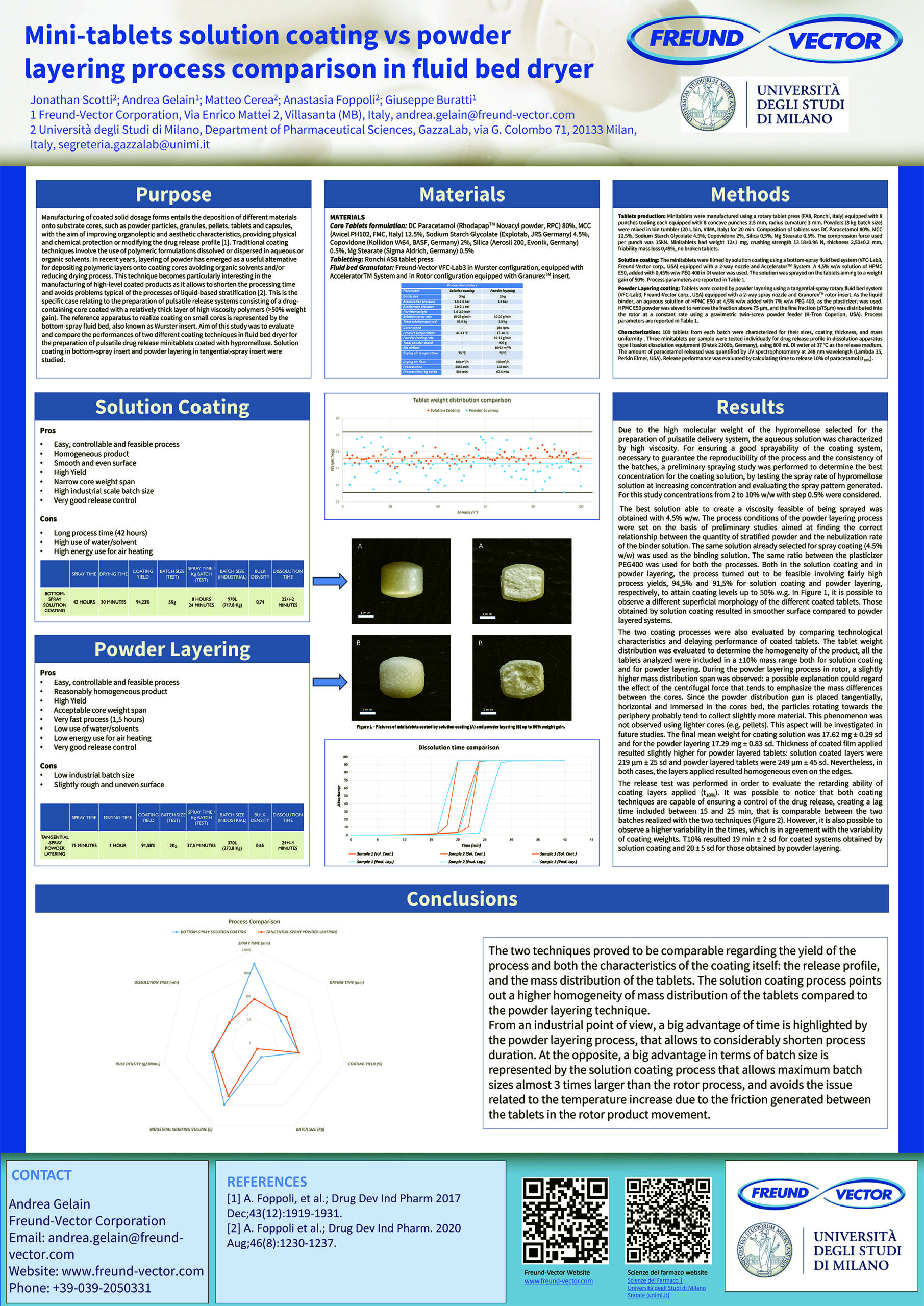

Solution Coating vs Powder Layering in Fluid Bed for Preparation of Hypromellose-Coated Minitablets per Stampa

Manufacturing of coated solid dosage forms entails the deposition of different materials onto substrate cores, such as powder particles, granules, pellets, tablets and capsules, with the aim of improving organoleptic and aesthetic characteristics, providing physical and chemical protection or modifying the drug release profile [1]. Traditional coating techniques involve the use of polymeric formulations dissolved or dispersed in aqueous or organic solvents. In recent years, layering of powder has emerged as a useful alternative for depositing polymeric layers onto coating cores avoiding organic solvents and/or reducing drying process. This technique becomes particularly interesting in the manufacturing of high-level coated products as it allows to shorten the processing time and avoids problems typical of the processes of liquid-based stratification [2]. This is the specific case relating to the preparation of pulsatile release systems consisting of a drug-containing core coated with a relatively thick layer of high viscosity polymers (>50% weight gain). The reference apparatus to realize coating on small cores is represented by the bottom-spray fluid bed, also known as Wurster insert. Aim of this study was to evaluate and compare the performances of two different coating techniques in fluid bed dryer for the preparation of pulsatile drug release minitablets coated with hypromellose. Solution coating in bottom-spray insert and powder layering in tangential-spray insert were studied.